Materials and Product Types

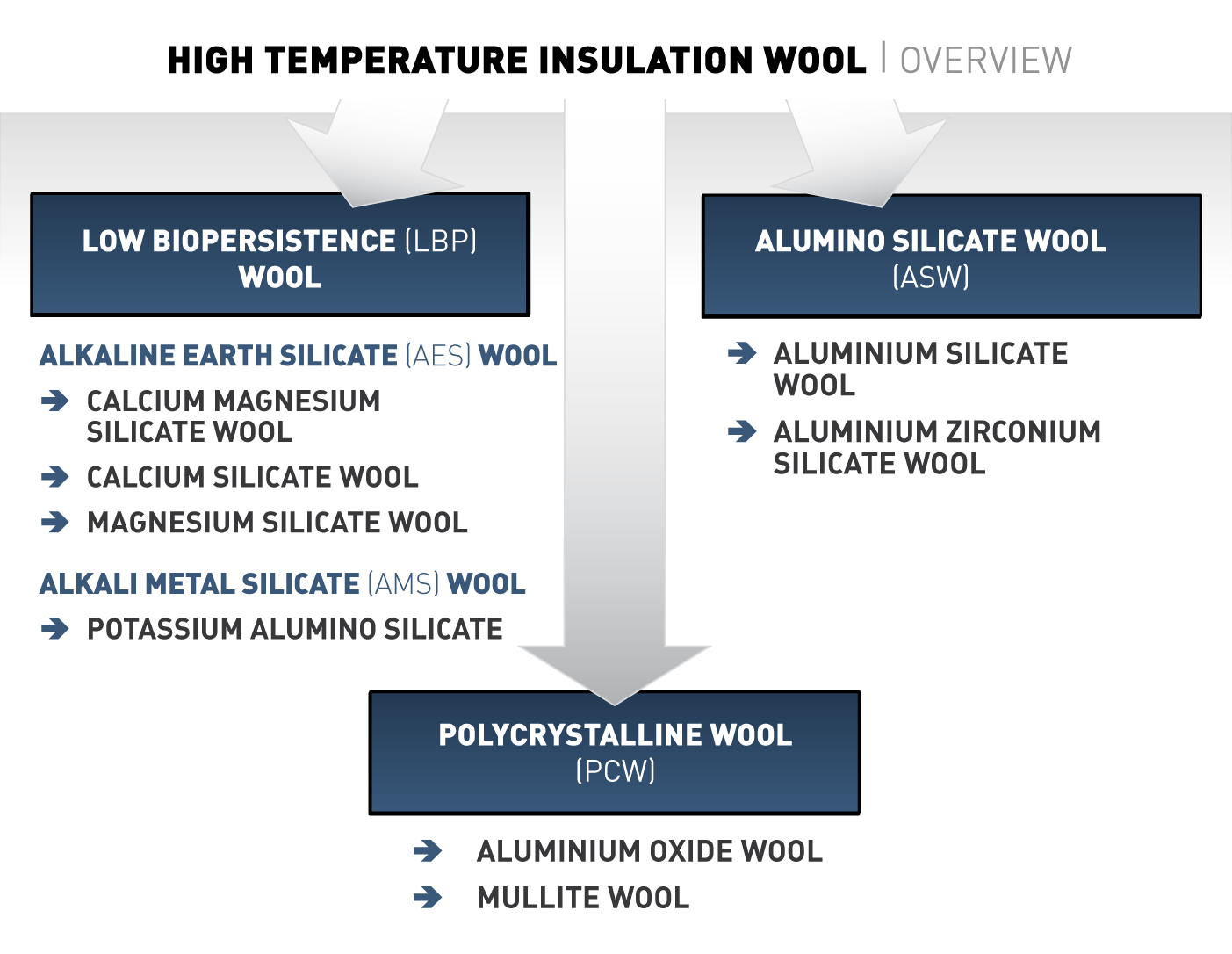

ECFIA’s members manufacture a range of High Temperature Insulation Wools (HTIWs) used in high temperature applications above 600°C. These are available in a range of product forms and preparations for subsequent processing or application. The three main types of HTIWs include:

- Low Biopersistent (LBP) Wool, including Alkaline Earth Silicate (AES) wools and others

- Alumino Silicate Wool (ASW), also known as Refractory Ceramic Fibres (RCF)

- Polycrystalline Wool (PCW)

All of the above materials have the appearance of cotton wool when manufactured. They are white with fibres forming a light fibrous mass or wool. Due to the nature of the fiberisation process, the wool contains fibres with a range of various lengths and diameters.

Product Forms

Product forms sold by ECFIA’s members can be described as follows:

Major Product Forms

- Bulk/Wool: The cotton wool-like material collected after fiberisation – is sold as feedstock to other processes or for some minor uses.

- Blanket: A mat of wool is converted to a blanket by „needling“. Pushing barbed needles into the mat and withdrawing them produces a coherent blanket. Blanket can be stacked or folded and compressed to produce modules.

- Modules: Retangular blocks ready for installation, for example, along furnace walls. Some modules have more complicated structures.

- Board: Rigid composite board containing a variety of organic and/or inorganic fillers and binders. Paper and Felt: Flexible composite often containing latex as a binder.

- Vacuum-Formed Shapes: Articles sometimes with complex shapes produced from wool mixed with fillers and binders in an aqueous suspension. They are then drawn into forms or moulds by vacuum where most of the water is removed. After further drying and finishing they can be supplied ready for installation with minimal further processing.

Other Product Forms

- Cement and Mastics: Sold as mixes or as mastics ready for installation.

- Textiles: Cloths, threads, ropes and yarns. A small proportion of HTIWs is converted into these forms for specialised applications.